Skills

As I have already mentioned, when I decided to build my CNC machine I wanted the build to be as easy as possible. I did not have a welding machine, milling machine, lathe or any other machines that could have assisted me in building my CNC machine. I even did not have cutting saws, drill press, tools to cut threads or do any other metal hand work. Nor did I want to do all this work myself, in part because I did not have the skills to do it properly; in part because I did not want to buy all these tools for a one-off project. Fortunately, we can order all crucial parts cut, drilled and tapped with very good tolerances (80/20 Inc. claims +/- 0.015" cut tolerance and 0.002/inch squareness which is excellent for our needs). This means that we will need only basic tools with a very few special machinist tools. But you will need to get these special tools if you plan to do CNC machining anyway.

However if you have the right tools and can do this work yourself, or if you want to cut down on building costs and ask your neighbor machinist (or your friend) to cut, drill and tap some aluminum you are welcome to do so. Note, however, that you will need some additional machines and tools. They are not included in the tools list below.

You will need to solder motor cables and terminate motors. It is not too difficult, but if you are not sure about your soldering skills, I suggest that you get help from somebody who can solder well enough to make a good solder joints. This is even more important because there are high currents involved, and they do not "like" bad connections. As for wiring the control circuit, almost all connections are made with screw terminals and pieces of wire, so you will need to either tin wire ends or terminate them for screw terminals.

You will also need to know how to make measurements correctly. We will use calipers, machinist square and dial indicator. These tools are relatively easy to use, but as all precise measurement tools they must be treated carefully.

Tools

Before you start assembling your CNC machine, make sure you have the following tools:

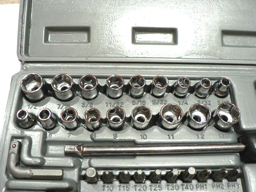

| Set of imperial and metric hex keys or drivers (we will mostly use 3/16" and 5 mm ones). |  |

| 5/16" socket tool. |  |

| Wrench for tightening 5/16" lock nuts. |  |

|

A pair of 3" - 5" clamps. One wide clamp (wider than 6", preferably wider than 8"). |

|

| Calipers. |  |

| Machinist square. |  |

| Dial test indicator (I recommend using 0.001" dial test indicator). |  |

| Soldering iron. |  |

| Lithium grease for bearings and silicon grease for steel rails (to lubricate and protect them from rust). |  |

This is an absolute minimum set of tools. You will need almost all of them during each and every step of your build.

Information And Parts

Knowing where to get the information you need and how to apply it is of utmost importance when accomplishing a project like this. I advise you at least to look through the sites listed below. Deep understanding of processes going on in the CNC machine will help you to build it faster and fine-tune it to its finest specs easier.

www.cnczone.com - this is your first place to start. This site has a great forum about milling machines, as well as lathes and other machines. There are quite a few threads where users describe their build progress; some machines are based on the same parts and assemblies as our machine.

www.cnccookbook.com - this site has very good articles explaining what is backlash and how it can be avoided. There are some useful tips and tricks too.

www.nookindustries.com - this site has very interesting in-depth information about ACME screws and nuts.

www.cs.uiowa.edu/~jones/step - this is a great place to learn about stepping motors and ways of controlling them. These articles give a very deep understanding of step motor controllers.

Below there is a list of suppliers.

www.8020.net - this is where you will order your aluminum extrusions. This site has very useful products catalogs and other important information.

www.machsupport.com - download Mach3 here. Read its documentation carefully before operating the software. Mach3 license key can be purchased from this site as well. Note that Mach3 software can operate without license in demo mode. Demo mode is fully functional, but is restricted to 500 lines of G-code.

www.geckodrive.com - this is where you get your G540. It is also a great source of information about stepping motors controllers. This site has an excellent FAQ section that can be understood even by a beginner in CNC.

www.cncrouterparts.com - this is where you will order some parts for linear motion components of your machine (particular information is given in the Bill of Materials).

www.finelineautomation.com - another source of parts for your machine (particular information is given in the Bill of Materials).

www.k2cnc.com - source of various router holders, collets and some machine tools.

www.mcmaster.com - source for ACME screws and fasteners.

www.mscdirect.com - source for bearings and fasteners.